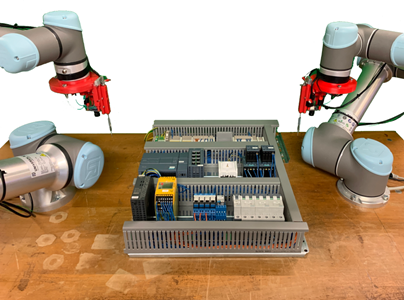

A dual-arm robotic platform for the autonomous testing of the electrical connections in a cabled switchgear has been developed and tested experimentally.

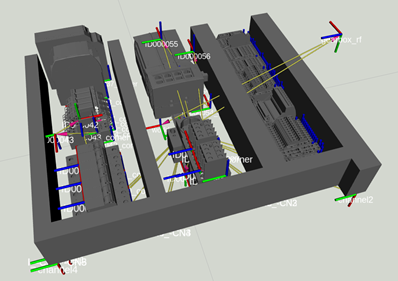

A knowledge database for the execution of the task is automatically generated directly from the product design platform. This database describes the list of components in the switchgear and all the connections to be tested.

Due to the potential misplacement of the component caused by manual assembly and cabling, a neural network trained on synthetic data is adopted for the precise detection in order to correct their position with respect to the expected position provided by the knowledge database. The connections are tested with a specific tool designed for the task provided with a 2D USB camera integrated in the end effector.

The proposed solution demonstrates the feasibility of this automation process at industrial scale, enabling both to have a fully monitored and repeatable quality control process and to save a significant amount of human work for this tedious and repetitive task.

Written by UNIBO